Efficient and reliable: Drying bricks & tiles under the best conditions.

Your success is our motivation - reliability is our job.

For more than 70 years, ROTHO has been providing high quality solutions for the brick & tile industry. We understand the requirements and the high competitive pressure of brick & tile manufacturers. In order to further increase the efficiency level of our customers' drying systems, we are constantly improving our products and systems. The production in our own factory in Germany guarantees a high quality standard and great flexibility. With more than 100 years of company experience, we know that success can only be achieved through close partnerships. We take this to heart when dealing with our customers and our employees. We develop our ROTHO systems with the aim of increasing production quantities and quality and to minimize downtimes of the plant. A close relationship with our customers is important to us in order to cooperatively create the best conditions for the brick & tile industry.

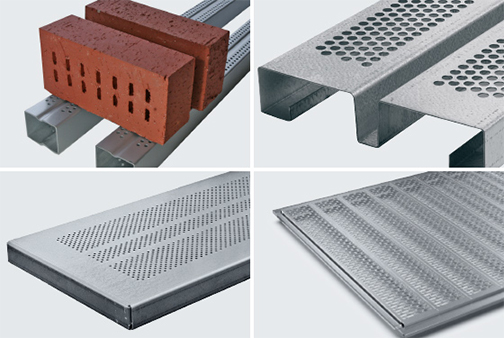

Reliable, individual, precise. Available as slats, racks, pallets, frames and large pallets.

- Different perforation designs for optimal ventilation

- Strip galvanized to stainless steel

- Process reliable and dimensionally stable with low dead weight

- Low system load

- Reduced heat absorption

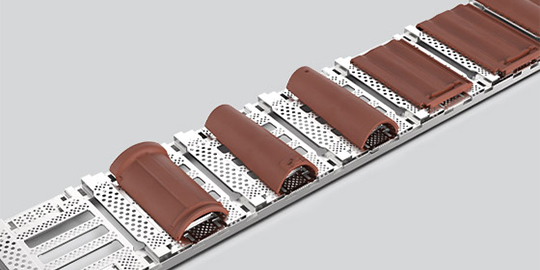

Optimally matched to flat tiles and accessory tiles. Reversible design possible for both variants.

- High air permeability

- Optimum use of space for maximum number of storage positions

- High dimensional stability with low dead weight through intelligent, constructive solutions (SEC)

- Reduced system load and heat absorption

- High precision of the support surfaces

Strong design for extreme loads

- Perfect straight run

- Low weight

- Minimized heat absorption

- Long service life

- Low maintenance

- Optionally with automatic maintenance unit

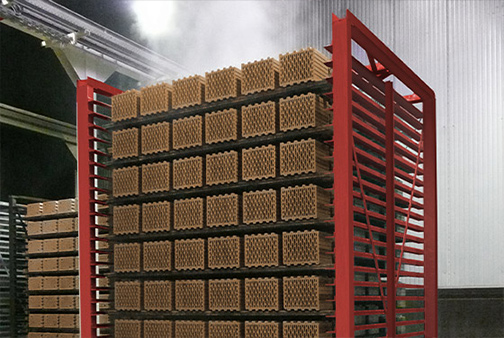

ROTHO QUATRO®: Fast building, safe drying

- Low storage heat

- Thermal bridge free construction

- Enormous impermeability

- High temperature resistance: Standard version up to 150°C,

- Demountable and reusable

- Ceiling can be walked on over the entire surface and can be subjected to high mechanical loads

- High corrosion resistance / condensate free inner surfaces

- 5 years warranty

The best ventilation technology for every tile

AirWall nozzle walls

- Flexible dryer widths and air speeds

- Low airflow shadows

- Drying time and quality gain due to reversing blowing with vertical discharge slots

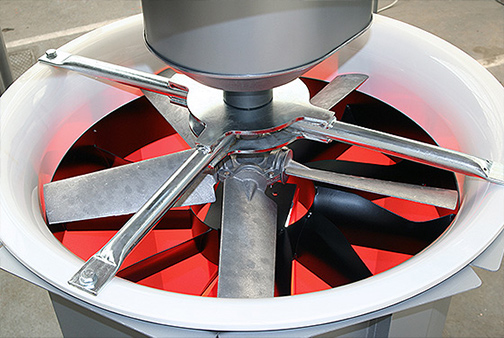

MixAir rotary fan

- Up to 25% lower electricity costs with the same circulation capacity

- Easy to maintain and robust

- Particularly uniformed outflow

- Large beam range

- Adjustable guide vanes

DriveAir mobile fan

- Higher efficiency compared to old mobile fans

- No temperature stratification

- Low maintenance

XStream Tile rapid dryer

- Up to 20% lower operating costs and thus reduced CO2 emissions

- Up to 60% less space required

- Reduction of drying times up to 75%

- Equal treatment of all green bricks in stock

- Targeted ventilation of individual brick sections

- Better drying results for difficult products

Modernization offer

- Generation of achievable drying curves in the mobile test dryer

- Measurement of airflow profiles in the dryer cross section

- Recording of drying curves in the operating dryer

- Preparation of energy and mass balances

- Indication of improvement potentials for existing plants

- Selection of the best drying technology for new plants

- Modernisation of obsolete ventilation systems

- Replacement of worn gates, structures, frames and drying supports

- Optimization of air and heat supply

- Energy optimisation

- Cooperation with the leading specialists and plant manufacturers in the industry

Diverse options

For a wide variety of concrete blocks.

Good work ensures satisfied customers

Downloads

Find out more about our solutions and the best possible conditions for your processes.

Impressions

Tile goods made with ROTHO